Noviomagus Bone Mill

The Noviomagus Bone Mill is a unique instrument developed for milling cortico-cancellous bone into bone grafts. The superior design and manufacturing leads to an easy to use instrument for orthopaedic and trauma surgeons that produces bone grafts of the highest quality. The milling of a femoral head into usable bone grafts can be achieved within one minute. The housing of the Noviomagus Bone Mill is made of a casted stainless steel alloy, which makes it an extremely solid device. There is no risk for abrasion. The milling drums are also made of a hardened stainless steel alloy to ensure a long lifespan. All together the Noviomagus Bone Mill is a long lasting and user friendly instrument with a minimal amount of parts and no disposable items.

- Quick and easy milling of cortico-cancellous bone

- Sustainable and durable, a long lifespan without any service or repair

- Creates bone grafts with an intact trabecular structure

- Mills fresh as well as fresh frozen bone

- Six different milling drums for a wide range of surgical indications

- Simple, efficient and user friendly design

Long life span

The Noviomagus Bone Mill is an extremely solid device without the risk for abrasion. The milling drums are made of a hardened stainless steel alloy. Even if used frequently the drums do not show any sign of wear. This combination guarantees high quality bone grafts and a durable instrument with no necessity for maintenance. The design prevents metal on metal contact, thus eliminating the risk of metal contamination of the bone graft. A warranty of five years is given for regular hospital use. No service, maintenance or replacement costs need to be made during these first five years, and probably many more. There are Noviomagus Bone Mills in use today which have a track record of 15 years of hospital use and are still working properly.

Bone grafts with an intact trabecular structure

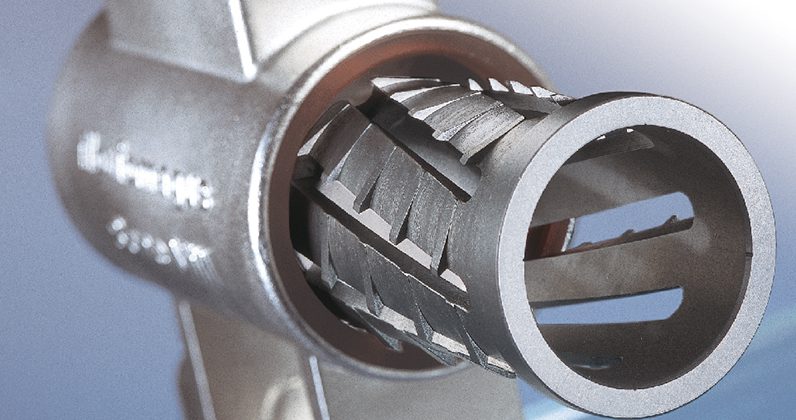

In order to create a stable and solid bone bed during bone impaction grafting procedures it is important to have bone grafts with an intact trabecular structure. The Noviomagus Bone Mill guarantees bone grafts with an intact trabecular structure because the milling technology is based on breaking out grafts rather than scraping off or crushing bone.

Six types of milling drums for different surgical indications

When using bone grafts during trauma-, orthopaedic-, maxillofacial- or spinal surgery, it is important to use grafts of the correct size. The Noviomagus Bone Mill has six interchangeable milling drums that are capable of producing a wide range of different chip sizes, fit for all surgical indications.

| Milling Drum | Application | Mean Length |

| Extra Coarse | Acetabular bone grafting | 10 – 15 mm |

| Coarse | Acetabular and proximal femoral bone grafting | 8 – 10 mm |

| Fine | Femoral and spinal bone grafting | 5 – 8 mm |

| Extra Fine | Distal femoral and spinal bone grafting | 3 – 5 mm |

| Extra Extra Fine | Spinal bone grafting and void filling | 1 – 3 mm |

| Extra Extra Extra Fine | Bone powder for dental and other indications | 0,5 – 1 mm |

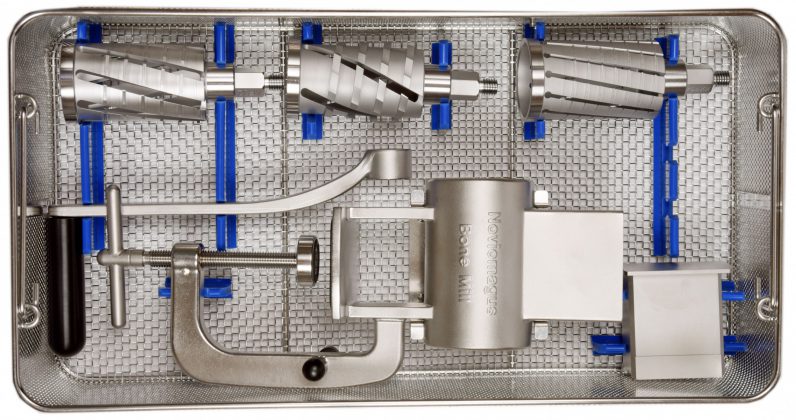

The Noviomagus Bone Mill is developed and manufactured by Spierings Orthopaedics BV, Nijmegen, the Netherlands. The standard operating kit of the Noviomagus Bone Mill consists of the following parts:

Standard Operating Kit Noviomagus Bone Mill |

|

| Article | Article Number |

| Housing | SBM-9801-02 |

| Push Block | SBM-9801-05 |

| Handle | SBM-9801-06 |

| Screw Nut | SBM-9801-07 |

| Sterilization Tray | SBM-0808-10 |

The Noviomagus Bone Mill has 6 different Milling drums. Please visit the additional information page to view the suggested surrigal indications for each milling drum. The basic sterilization tray can hold three milling drums. An additional sterilization tray is available to accomodate additional milling drums for sterilization and storage.

| Milling Drum Options | Article Number |

| Extra Coarse | SBM-0903-11 |

| Coarse | SBM-9801-04 |

| Fine | SBM-9801-03 |

| Extra Fine | SBM-9801-08 |

| Extra Extra Fine | SBM-0604-09 |

| Extra Extra Extra Fine | SBM-1207-59 |

| Optional | Article Number |

| Milling Drum Sterilization Tray | SBM-1303-61 |

*The regular Sterilization Tray holds 3 milling drum. When purchasing more than 3 drums this additional sterilization tray is advisable.

When ordering the Noviomagus Bone Mill, please make a selection from the different drum sizes described above. Our account managers and distributors are available to provide you with advice on the drum size selection based on your needs. Feel free to contact them with the contact form. In case you are looking for orthopedic instruments for surgical use, please visit www.spierings.biz.

Noviomagus Bone Mill

The Noviomagus Bone Mill and its milling drums are made of solid surgical stainless steel, hardened where necessary.

This bone mill has no aluminium housing, and no sheet metal milling drums. All parts are made of solid materials that are extremely wear resistant. The bone is cut, rather than scraped off. The ratio between milling drum size and the handle, and the spirally positioned teeth on the milling drums render a smooth movement.

We offer a two year warranty on all parts, including the milling drums’ teeth, for use in tissue banks.

We have customers throughout the world that have been using the Noviomagus Bone Mill for many years. Amongst them we can mention Perth Bone & Tissue Bank (Australia), Musculoskeletal Transplant Foundation (MTF, United States), Lifenet Health (United States) and many other bone banks and hospitals.

+31-(0)24-3501603

tissue-processing@spierings.biz